| Sign In | Join Free | My enlightcorp.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My enlightcorp.com |

|

Brand Name : HWASHI

Model Number : WL-SQ-50kx4

Certification : CE/CCC/ISO

Place of Origin : China

MOQ : 1 set

Price : negotiation

Payment Terms : L/C, T/T

Supply Ability : 50 sets per month

Delivery Time : 7-30 working days after received your payment

Packaging Details : sea worthy wooden package

Product Name : HWASHI CNC System Automatic Sheet Metal Plate Welder

Application : Widely used to Weld Sheet Metal

Size : 1200x1180x1850mm

Weight : 400kg

Condition : New

The size of working table : 1400mmx1300mm

Effective Welding Width : 1350mm

Service Life : 8-10 years

HWASHI CNC System Automatic Sheet Metal Plate Welder

DESCRIPTION

Intellectual touch-screen microcomputer controller,completely digital control,automatic detection and compensation,loose welding and false welding are well prevented.

Panasonic touch-screen hunan-computer interface,Panasonic programer is adopted as the control hub, in charging of reading and dealing with control signal to gurrantee that the machine operartion is in order and effective.

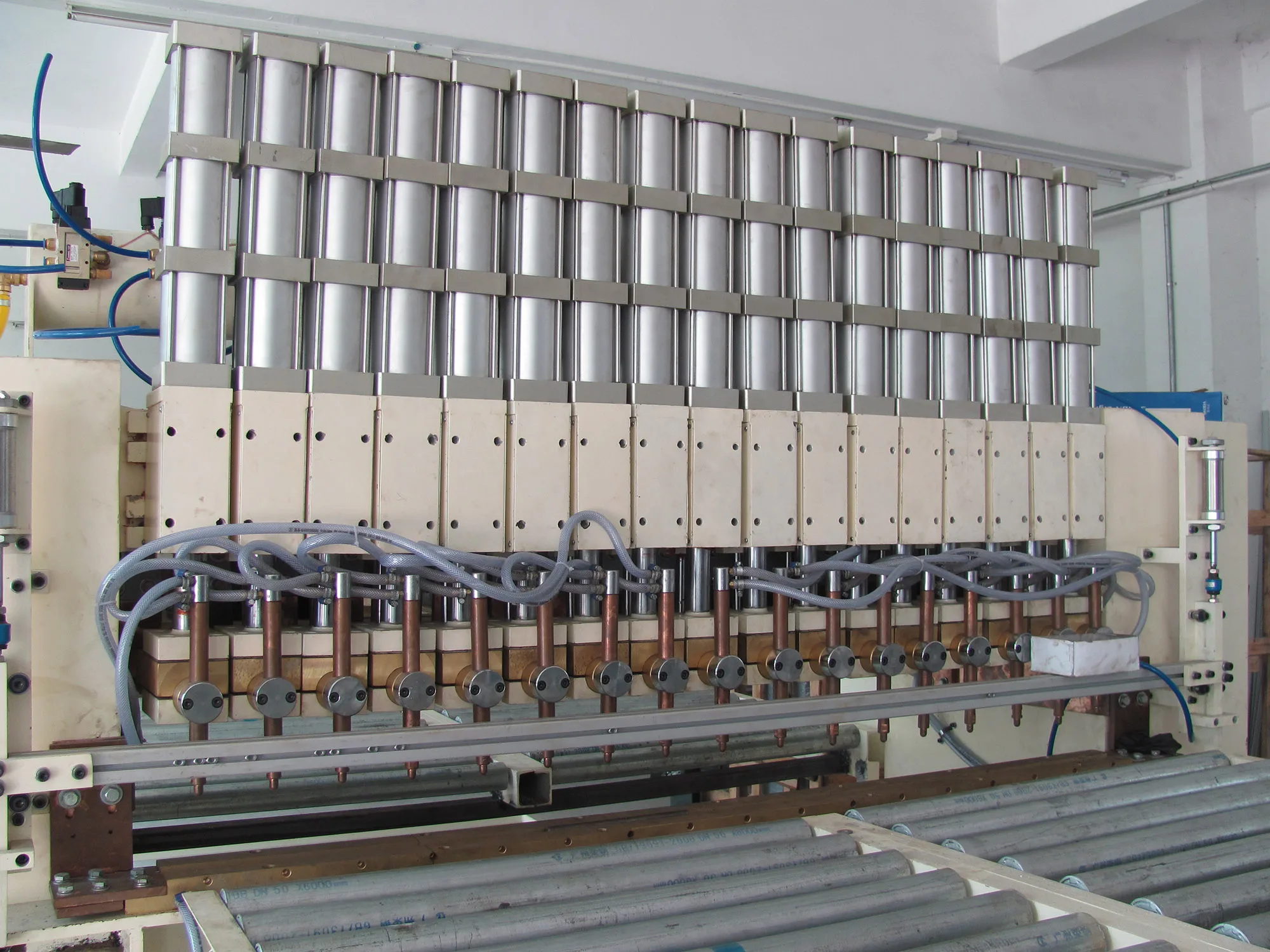

Groups of welding electrodes can be moved from left to right,all kinds of products are suitable to be welded. Welding electrodes can work in flexible order. No metal sheet deformation.

Pneumatic mechanism, the perssure of every electrodes can be adjusted, stable force is achieved. The upper electrodes have an adjustable working distance forwards and afterwards, the lower electrode mould installation is simple and flexible to be adjusted from left to right.

Encoding servo motor feeding rack mechanism, equipped with high precise slide guide and automatic detection device. Has the advantages of quick reaction, high precise control, powerful engine, and high effeciency.

SPECIFICATION

| S.N. | Items | Parameters |

| 1 | Input voltage | 380V,2 phase |

| 2 | Input current | 395A |

| 3 | Output voltage | AC11.6V |

| 4 | Max.short-circuit current | 40000A |

| 5 | Welding Models | 16 sets |

| 6 | Welding Position | 5000 points |

| 7 | Different welding current | 4 sets |

| 8 | Effective welding width | 1000mm (customized) |

| 9 | Effective welding length | 1200mm (customized) |

| 10 | Rack mobile speed | 600mm/sec |

| 11 | Rack mobile power | Servo motor |

| 12 | Cross wire feeding system | 1 set |

APPLICATION

widely used to weld metal sheet in electronic appliances, automobile and other industries.

Main body: It adopts longitudinal stress body and good quality thick steel plate to ensure the strength and stability of the main body.

Welding Power Source: Choose the small power 150KW discharging transformer which is special used for resistance welding as the welding power source. To ensure the strength and stability of the welding,

Welding Control System: The secondary which is controlled by microcomputer will identify the output of current automatically in order to guarantee the constant current of each welding spot. In the meantime, the control system is equipped with the function of voltage compensation which is used for the automatic detection of the voltage change in order to ensure the constant strength of the welding spot.

Pressurized Mechanism: Multiple pressurized mechanisms are adopted to drive the row welding electrodes to conduct welding to each wire respectively.

|

|

CNC Sheet Metal Plate Welder With Microcomputer Controller Images |